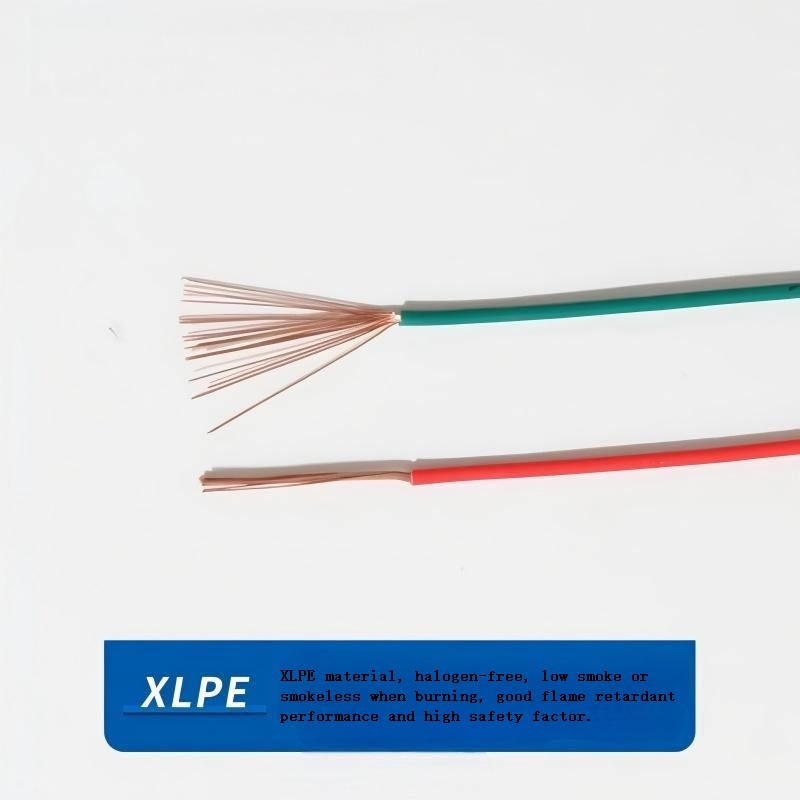

Cross-linked Polyethylene (XLPE): Revolutionary Development and Market Potential Customer in Cord and Wire Insulation Materials

A cutting-edge material with a three-dimensional network framework, cross-linked polyethylene (XLPE) has actually reshaped international power transmission by pushing the warm resistance limitation of polyethylene from 70 ° C to over 100 ° C. XLPE-insulated wires have changed the technical landscape, with lasting operating temperature levels raising from 70 ° C to 90 ° C and short-circuit allowed temperature levels from 140 ° C to 250 ° C compared to standard PVC cables. This architectural improvement through cross-linking technology improves mechanical residential properties, environmental tension resistance, and chemical deterioration resistance, making XLPE a core material for high-voltage transmission, brand-new energy grid link, and metropolitan below ground grids.

1.Product Revolution: Core Advantages and Performance Innovations of XLPE

XLPE converts straight polyethylene molecular chains into a three-dimensional network by means of physical or chemical techniques, bringing essential efficiency renovations:

- Electrical Efficiency : Maintains outstanding insulation with high insulation resistance and low dielectric loss tangent, secure even at high temperatures.

- Thermal Performance : Withstands decay below 200 ° C, with a 90 ° C long-term functioning temperature and 40-year life span, much going beyond typical PE’s 70 ° C restriction.

- Mechanical Performance : Enhanced hardness, stiffness, and influence resistance, overcoming environmental anxiety splitting.

- Environmental Safety : Burning creates only H TWO O and CO TWO, ideal for below ground stocking dense areas.

| Efficiency Indicators | XLPE | Common PE | PVC |

|---|---|---|---|

| Lasting working temp. | 90 ℃ | 70 ℃ | 70 ℃ |

| Short-circuit temperature. | 250 ℃ | 140 ℃ | 160 ℃ |

| Life span | 40 years | 20– 25 years | 15– twenty years |

| Burning items | H ₂ O, CO TWO | Black smoke, harmful gas | Chlorine, hazardous smoke |

2.Refine Advancement: Competition and Development of 3 Cross-linking Technologies

Three mainstream modern technologies dominate XLPE wire manufacturing:

- Inert Gas Cross-linking (Dry Chemical) : Makes use of peroxide agents, appropriate for 500kV high-voltage cables with excellent electrical residential properties.

- Silane Chemical Cross-linking (Cozy Water) : Hydrolyzes in 85– 95 ℃ water, limited to 10kV medium-low voltage due to moisture absorption.

- Irradiation Cross-linking (Physical) : Makes use of electron accelerators, ideal for ≤ 6kV wires with exceptional warm resistance.

3.Market Framework: Global Landscape and Regional Differences

In 2022, the worldwide XLPE insulation market got to ¥ 9.46 billion, anticipated to strike ¥ 15 billion by 2029 (CAGR 6.71%):.

- China : Controls with a ¥ 4.61 billion market (48.77% international share in 2022), forecasted to get to ¥ 7.94 billion by 2028 (52.88% share).

- Capacity : China created 325,000 bunches (46.38% worldwide) and offered 368,000 loads (52.56% international) in 2022.

- Competition : Global market led by Dow (23.86% share); China’s Wanma Polymer holds 32.48% domestic share.

4.Application Circumstances: New Power and Facilities Need.

- High Voltage (≥ 110kV) : Preferred for underground/submarine HVDC transmission, e.g., Sumitomo’s 400kV DC XLPE wire order in Abu Dhabi.

- Medium Voltage (10– 35kV) : Widely made use of in metropolitan grids, industrial parks, and wind farms.

- New Power : Offshore wind power demand expanded fastest, reaching 28,000 tons in 2022 (14.55% forecasted CAGR). China’s 1,200 GW renewables strategy by 2025 will certainly drive need.

- Building : Halogen-free, low-smoke homes make XLPE ideal for high-rises and metros, making up 20% of complete demand in 2023.

5.Technological Advancement: Product Science and Process Optimization.

- UV Cross-linking : Solves typical approaches’ high energy intake and slow reaction rate, improving harmony.

- Product Solution : Borealis’ “Borlink” HVDC substance allows low-loss transmission and recyclability, used in Germany’s Passage job.

- Water-tree Resistance : New products prolong life span to > 40 years in moist atmospheres.

- Intelligent Production : > 70% of Chinese companies aim for smart production by 2025, optimizing criteria through IoT.

6.Difficulties and Potential Customers: Market Patterns.

- Obstacles : Rising and fall PE rates, competitors from PP/HDPE, and more stringent ecological laws (China’s 2023 power usage down 10%).

- Trends :.

- HVDC tasks (e.g., UK-Belgium Nemo Link) drive high-voltage demand.

- Environment-friendly production: China’s reusing price reached 35% in 2023, up 10% from 2022.

- Temperature level resistance: Future materials may enhance heat resistance by 10% and mechanical stamina by 15%.