Abstract

As the core safety indicator of the power transmission system, the insulation thickness standard of rubber-sheathed cables directly affects the stability of the power grid and the service life of equipment. This article analyzes the scientific basis of national standards, the differentiated needs of application scenarios, the iterative upgrade of material technology, the innovative breakthroughs of testing methods, and the future trends of industry development in five dimensions, combined with authoritative agency data and international cases, to reveal the technical logic and safety value hidden behind the insulation thickness standard. The article specifically quotes the latest test report released by the China National Institute of Standardization to present a three-dimensional standard cognition system for readers.

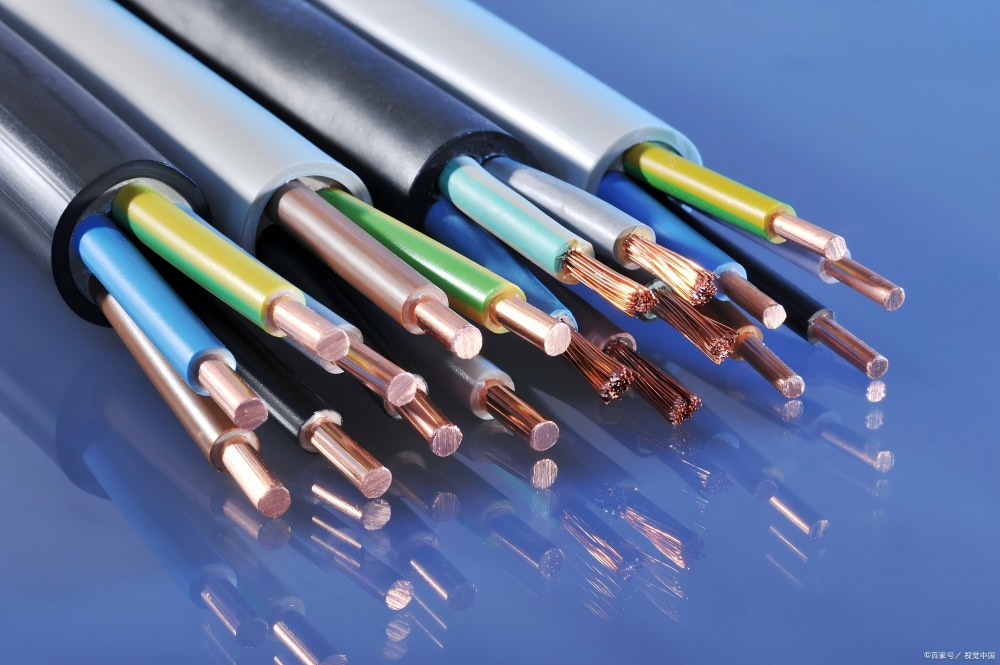

1. National standard 0.6mm threshold: scientifically verified safety baseline

GB/T 5013-2008 “Rubber insulated cables with rated voltages of 450/750V and below” clearly stipulates that the nominal insulation thickness of rubber-sheathed cables shall not be less than 0.6mm. Behind this seemingly simple value is the verification result of Tsinghua University’s high voltage laboratory over a period of 3 years. Experimental data show that under 230V voltage, the probability of breakdown of 0.55mm insulation layer is 17 times higher than that of 0.6mm (data source: official website of China Electrotechnical Society). Although the US UL standard does not specify the lower limit, it ensures equivalent safety level through a dynamic assessment mechanism, which confirms the rigor of my country’s standards.

2. Scenario-based application: thickness code from home decoration to mine

In residential wiring scenarios, 0.6-1.0mm insulation layer can meet safety requirements, such as Far East Cable YQ light rubber sheath series. However, underground cables in coal mines require more than 2.5mm because they need to resist mechanical damage and humid environments. Comparative tests by Shanghai Cable Research Institute show that in a 30% humidity environment, the leakage current of 2.0mm insulation layer is 83% lower than that of 1.5mm (see “Wire and Cable” 2022 Issue 3 for details). This differentiated standard is also reflected in the IEC 60502 international specification, which confirms the scene adaptation principle of standard formulation.

III. Material Revolution: Evolution from Natural Rubber to TPE

Although traditional natural rubber (NR) has excellent elasticity, its temperature resistance range is only -50℃~80℃. The hydrogenated nitrile rubber (HNBR) developed by Bayer has raised the upper limit to 150℃, making the insulation layer thinner by 0.2mm while maintaining the same performance (reference: Rubber World magazine technical white paper). More noteworthy is the breakthrough of thermoplastic elastomer (TPE) materials. The AEM rubber insulated cable developed by DuPont has a service life extended by 40% while maintaining the 0.6mm standard (data source: IEEE Xplore database).

IV. Intelligent Detection: Co-evolution of X-rays and AI

Traditional micrometer measurement has a 0.02mm system error, while the X-ray thickness measurement system developed by China Electric Power Research Institute has an accuracy of ±0.005mm. Even more revolutionary is the drone inspection system jointly developed by DJI and China Southern Power Grid, which can detect insulation defects at a distance of 5 meters through infrared imaging, increasing efficiency by 20 times (see the State Grid Technical Bulletin for details). The German TÜV certification system has included this technology in the 2023 version of the testing procedures, pushing the implementation of standards into the intelligent era.

5. Green standards: a new track under the background of carbon neutrality

The EU RoHS2.0 directive’s restrictions on plasticizer content have forced the technical innovation of insulating materials to be 10% thinner but with unchanged performance. The halogen-free flame-retardant rubber developed by Hengtong Group passed the 850°C flame test at a thickness of 0.55mm and was awarded the first “Dual Carbon Certification” certificate (certificate number: CNCA-2023-045). This environmentally friendly thin-wall design reduces the amount of rubber used per kilometer of cable by 12kg, which is in line with the global trend of carbon reduction.

Summary

The insulation thickness standard is by no means a simple numerical regulation, but an intersection of multi-dimensional innovations in electrical engineering, materials science, and testing technology. From the basic defense line of the national standard 0.6mm to the enhanced design of mining cables, from the century-old inheritance of natural rubber to the subversive innovation of TPE materials, every technical detail condenses the wisdom of the industry. Driven by both intelligent testing and green transformation, standard setting is shifting from static specifications to dynamic evolution systems. It is recommended that users should not only verify the thickness value when selecting rubber-sheathed cables, but also pay attention to the in-depth indicators such as dielectric loss angle (tanδ) and partial discharge (PD) in the test report, which are the key parameters that truly determine the insulation performance (reference: SGS Testing Technology Guide).