Nationella standardkablar: säkerhetens grundbult för att skydda tusentals lampor

——Varför varje meter kabel tål livets mått

Data från ministeriet för krishantering visar att det under det senaste decenniet har inträffat mer än 100 större brandolyckor orsakade av kabelproblem i mitt land, vilket står för mer än 50 % av det totala antalet bränder**. Icke-standardkablar är som tickande bomber som lurar i väggarna i tusentals hushåll.

År 2025 riktade CCTV:s 315-gala återigen strålkastarljuset mot tråd och kabel industrin och avslöjade kaoset med öppen försäljning av "icke-standardkablar" på South China Hardware Market: handlare lockar kunder till låga priser, snålar in på kopparkärnan i produkterna och använder undermålig återvunnen plast för isoleringsskiktet och tillhandahåller till och med "one-stop counterfeiting"-tjänster - utseendet skiljer sig inte från den nationella standardkabeln, och kvalifikationsrapporten kan förfalskas.

Bakom denna säkerhetskris ligger vikten av otaliga liv. Att välja nationella standardkablar är inte bara ett åtagande om kvalitet, utan också en respekt för livet.

1. Blod och tårar-varning: icke-standardkablar är osynliga brandbomber

Statistik från ministeriet för krishantering visar att kabelproblem har blivit den främsta orsaken till brand. Under de senaste tio åren stod större brandolyckor orsakade av kablar i landet för mer än 50 % av det totala antalet bränder, varav icke-standardkablar var boven i dramat.

År 2020 dödades en brandman och sex personer skadades i en brand på Chengguan Trade Market i Nandan County, Guangxi; 2013 orsakade en brand på Rongjian Agricultural Wholesale Market i Shenzhen 16 dödsfall och direkta ekonomiska förluster på 17,81 miljoner yuan – den direkta orsaken till båda olyckorna var kortslutning i elledningen.

Kablar av dålig kvalitet är som "kruttunnor" begravda i väggen. När de väl är överbelastade eller kortslutna smälter isoleringsskiktet omedelbart och fattar eld, och de giftiga gaserna som väteklorid som frigörs vid förbränningen kommer att blockera flyktvägen.

2. "Kärnstöldsteknik" driven av vinster: Metoderna för förfalskning av icke-standardkablar avslöjas

Olagliga tillverkare använder fyra huvudsakliga metoder för att minska kostnaderna till mindre än 60 % av den nationella standardkabeln:

- Snåla in på kopparkärnan: Den faktiska tvärsnittsarean för den nominella 4 mm² kopparkärnan är endast 2,5 mm², och det ökade motståndet gör att värmen stiger kraftigt;

- Vinstdrivande genom att dopa med föroreningar: Återvunnen koppar som innehåller järn och zink används för att ersätta syrefri koppar, vilket accelererar oxidationskorrosion;

- Isoleringsskiktet är undermåligt: "Andra generationens material" (återvunnen PVC) används för att ersätta jungfruliga material, med en prisskillnad på 2 000 yuan per ton, vilket är benäget att åldras och spricka;

- Skyddsfunktion kastrering: Antalet glimmerbandlager i brandbeständiga kablar reduceras från den nationella standarden till 1-2 lager, och den flamskyddande barriären går förlorad i brand.

Den "2,5 kvadratmillimeter kabel" som köptes av Mr. Liu i Changsha, Hunan testades av Shaanxi Xiecheng Testing Technology Company. Kopparkärnans diameter är mindre än 80 % av den nationella standarden 1,78 mm, och motståndsvärdet överskrids allvarligt.

3. Allmän säkerhet kollapsar: Hur undermåliga kablar hotar sociala system

När icke-standardkablar infiltrerar offentliga arbeten förstoras skadan exponentiellt. Hunan Fengxu Cable Co., Ltd. avslöjades sälja undermåliga kablar. Dess anbudshandlingar visar att företagets produkter har kommit in i svagströmssystemen i 5 skolor, inklusive Changsha Mingde Middle School och Yuhua District Huahou Primary School.

Potentiella katastrofkedjor inkluderar:

- Brandrisk på campus: Det finns begränsade flyktvägar på trånga platser, och undermåliga kablar antänder taket och sprider sig snabbt;

- Nödsystemförlamning: Om kommandocentralens kabel går sönder i förväg i en brand kommer avbrottet i övervakningen att fördröja den gyllene räddningstiden;

- Finansiella medel avdunstar: Omkostnaderna som orsakas av att bryta väggen och byta ledning överstiger kabeln i sig. Budgeten för omvandlingen av elnätet på en viss plats överskreds med 300 % på grund av okvalificerade kablar.

4. Det tredubbla skyddsskölden för nationella standardkablar: certifiering, teknik och ansvar

1. Obligatoriskt certifieringssystem bygger en stark brandvägg Nationella standardkablar måste klara CCC-certifiering (China Compulsory Product Certification). De nya reglerna 2025 kräver:

- Isoleringsskiktets tjockleksfel är ≤0,02 mm, och den flamskyddande kabeln måste klara GA 306.1-2025 rökdensitetstest;

- Varje meter kabel är permanent märkt med CCC-märket + fabriksnummer (t.ex. 123456) för att uppnå kvalitetsspårbarhet.

2. Teknisk innovation förbättrar säkerhetströsklarna Ta 110 kV polypropenkabeln som utvecklats av Baosheng High Voltage som ett exempel:

- Temperaturmotståndet når 110 ℃ (20 ℃ högre än traditionella kablar), och strömförande kapacitet ökar med 10 %;

- Produktionscykeln förkortas med 30 %, koldioxidutsläppen minskas med 35 %, och den kan återvinnas under hela livscykeln.

3. Institutionalisering av företagens ansvar Far East Cable har etablerat en "dubbel noll" (noll defekter, noll klagomål) kvalitetsstandard, öppnat upp tredjepartsövervakning på plats och blivit det företag med mest utrustning ansluten till State Grids övervakningsplattform. Dess dynamiska utvärderingsmekanism för leverantörer säkerställer att renheten hos kopparmaterial är ≥99,99 %, vilket blockerar föroreningsdopning från källan.

5. Tre knep för att identifiera icke-standardfällor: Konsumentens självskyddsguide

1. Certifieringsverifiering

- Leta efter CCC-märket + fabrikskoden tryckt var 500:e mm på tråden;

- Skanna QR-koden för certifikatet för att kontrollera certifieringens giltighet (Certification and Accreditation Administration kommer att vara obligatorisk att ansluta till Internet från 2025).

2. Fysisk testmetod

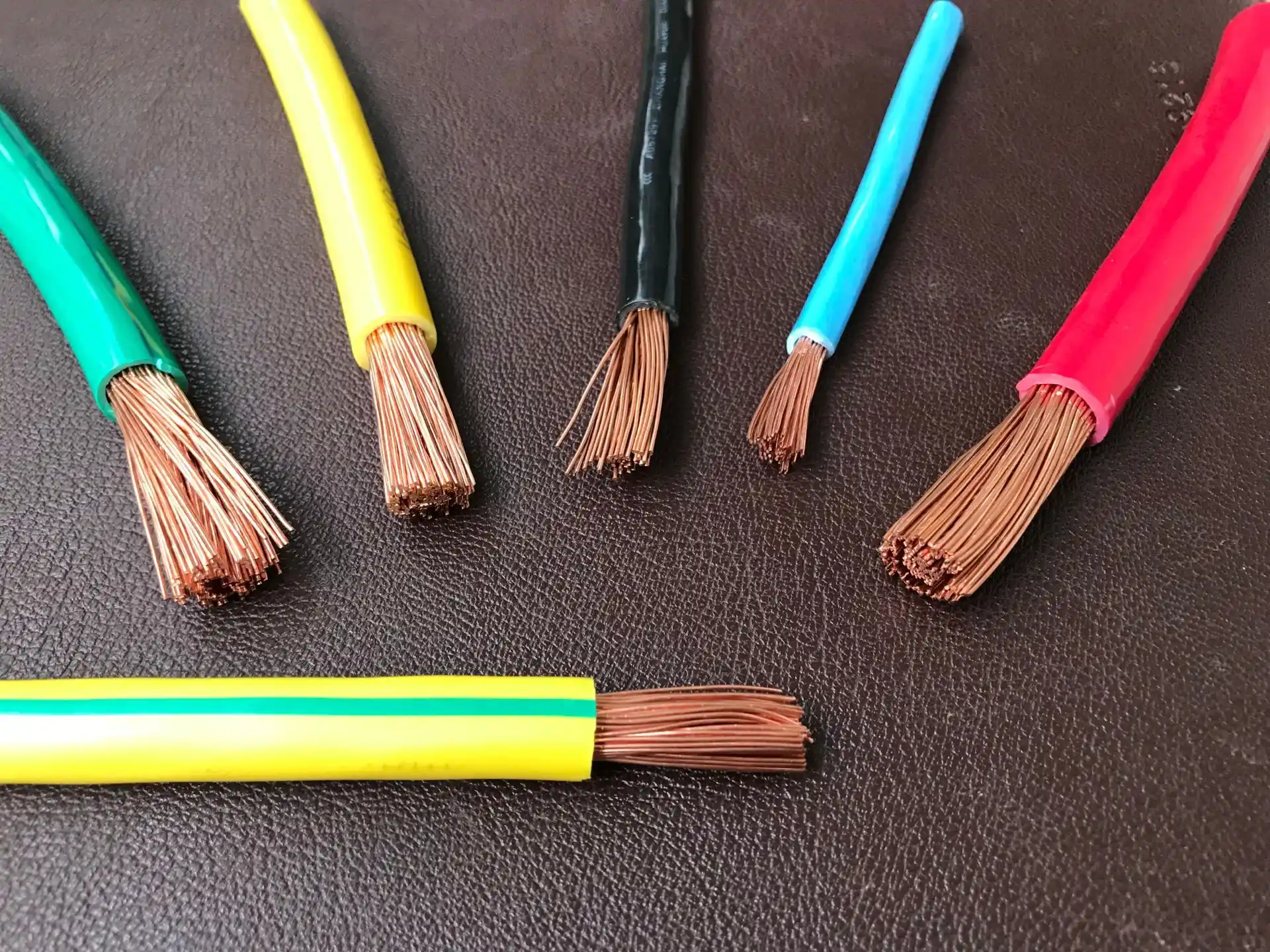

- Identifiering av kopparkärna: Högkvalitativ kopparkärna är purpurröd och inte lätt att bryta när den böjs; sämre produkter är mörka och fläckiga och går sönder efter 3 vikningar;

- Isolationsskiktstest: Vita märken som lämnas av att skrapa med naglarna eller vitna genom att klämma är mestadels återvunnen plast;

- Storleksverifiering: Diametern på 2,5 mm² kopparkärna bör vara 1,78 mm, och bromsmätarens mätavvikelse är >5 % är misstänkt.

3. Kanalval

- Håll dig borta från "40-50 % rabatt på lågprisledningar". Priset på icke-standardkablar på en viss järnaffärsmarknad är bara 40 % av de nationella standardkablarna, vilket döljer enorma risker;

- Be om fakturor och behåll prover. Mr. Liu i Changsha låste Fengxu Cables ansvar baserat på testrapporten.

6. Industriellt genombrott: standarduppgradering och teknisk revolution

Den nya nationella standarden GB/T 5054.1-2024 som implementerades 2025 kommer att öka oljebeständigheten och böjningsradien för bilkablar med 30 %, vilket tvingar företag att uppgradera sin teknik.

Baosheng High Voltage och Tsinghua University utvecklade gemensamt en polypropenkabel. Genom COMSOL-simulering optimerades produktionsprocessen och tvärbindningslänken eliminerades för att eliminera föroreningen av tvärbindningsbiprodukter. Industri-universitet-forskningsgruppen vid State Grid Liaoning Company har hjälpt mitt land att bryta igenom beroendet av import för högspänningskabelisoleringsmaterial.

Ledande företag som Far East Cable har deltagit i utformningen av mer än 150 internationella och inhemska standarder, vilket främjar transparensen för viktiga parametrar som antalet glimmerbandlager och mängden tillsatt flamskyddsmedel.

Att använda ett bromsok för att mäta diametern på kopparkärnan är också att mäta samvetets tjocklek; att använda ett isolerande skikt för att isolera strömmen är också att isolera girighet från livet. När generaldirektören för Hunan Fengxu Cable krossade kameran, krossade han företagets ansvarskontrakt gentemot samhället; när Baosheng High Voltages polypropenkabel klarade 110 ℃ temperaturmotståndstest, tände den gnistan av självdisciplin inom industrin.

Att välja nationella standardkablar är att välja att begrava en säker kinesisk mur i väggen – den kommer inte att kompromissa med tjockleken på grund av rabatter och kommer inte att bränna livet på grund av låga priser. Freden för tusentals lampor är alltid byggd på en bra "kärna" som tål mätning.

Utökad auktoritativ läsning: State Administration for Market Regulation "Wire and Cable CCC Certification Rules": [http://www.cqc-3c.com/case/1616.html] Ministeriet för krishantering Elektrisk brandrapport: [www.bzs.gov.cn/info/1103/43919.htm] State Grid Polypropylene Cable Technology White Paper: [https://www.cannews.com.cn/chanye/2025/07-17/XkJOY7b1.html]

Vanliga frågor

F1: Varför är icke-standardkablar livshotande?

S: De använder undermålig koppar och återvunnen PVC, vilket orsakar överhettning, kortslutningar och giftiga bränder (som man såg i Shenzhen 2013-tragedin).

F2: Hur identifierar man falska GB-kablar?

S: Kontrollera obligatoriska CCC-märken + fabrikskod tryckt var 500:e mm; mät koppardiametern (t.ex. 1,78 mm för 2,5 mm²).

F3: Vad är nytt i 2025 GB-standarder?

S: Strängare rökdensitetstester (GA 306.1-2025) och permanenta spårbarhetskoder på kablar.

F4: Kan billiga kablar påverka den allmänna säkerheten?

S: Ja. Skolor/sjukhus som använder icke-standardkablar riskerar massiva evakueringsfel (t.ex. Changsha skolprojektfall).

F5: Vilka märken uppfyller sanna GB-standarder?

S: Leta efter Far East Cables "Zero Defect"-certifiering eller Baoshenghighvoltages polypropeninnovation.