Abstract

As the core component of modern power transmission, the performance and safety of rubber-plastic cables are directly related to the stable operation of the energy system. With the advancement of materials science and testing technology, the production standards, material selection and test methods of rubber-plastic cables have been continuously upgraded, forming a full-chain specification system from manufacturing to application. This article analyzes from six dimensions, including material composition, production process, testing standards and international specifications, and combines authoritative standard documents with industry practices to comprehensively analyze the technical development and application challenges of rubber-plastic cables.

1. Composition and material innovation of rubber-plastic cables

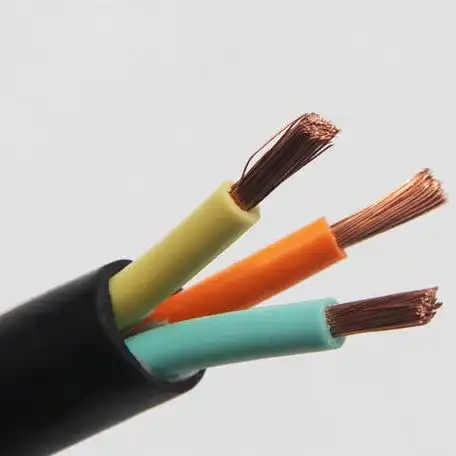

The basic structure of rubber-plastic cables consists of four parts: conductor, insulation layer, shielding layer and sheath (Figure 1). Among them, the choice of insulating material directly determines the upper limit of the performance of the cable. For example, cross-linked polyethylene (XLPE) is widely used in medium and high voltage cables due to its molecular mesh structure and temperature resistance of 90~130℃; ethylene-propylene rubber (EPR) has become the first choice for mobile scenarios (such as mining cables) due to its flexibility and ozone resistance.

In recent years, the popularization of irradiation cross-linking technology has further improved the aging resistance of materials. For example, the temperature resistance level of radiation cross-linked rubber and plastic elastomer cables exceeds 125°C, and they have both flame retardant and oil resistant properties. They have been successfully used in high-demand fields such as nuclear power plants and aerospace. In addition, the optimized formula of environmentally friendly plasticizers (such as DOP) not only reduces the dielectric loss of polyvinyl chloride (PVC) cables, but also meets the safety requirements of special scenarios such as food packaging.

2. Key processes and quality control of production technology

The production of rubber-plastic cables requires strict processes:

- Conductor twisting: Multiple copper or aluminum wires are twisted to improve conductivity and mechanical strength;

- Insulation extrusion: Rubber or plastic is evenly coated on the conductor under high temperature and high pressure. Temperature and pressure control directly affect the density of the insulation layer;

- Sheath molding: The outer sheath must have water resistance and cold resistance. In some scenarios, a braided layer must be added to enhance wear resistance;

- Post-processing and testing: Cutting, embossing, and electrical performance testing (such as partial discharge testing) to ensure the quality of the finished product.

Taking cross-linked polyethylene cables as an example, its core process lies in the cross-linking reaction – converting linear molecules into a three-dimensional mesh structure through chemical or irradiation methods, thereby greatly improving heat resistance and mechanical strength.

3. The core position of testing standards and test methods

The testing standards of rubber-plastic cables are the cornerstone of ensuring their reliability. Taking the GB/T 3048 series standard as an example, it covers 12 test methods such as insulation resistance, withstand voltage, dielectric loss, etc., for example:

- Insulation resistance test (GB/T 3048.5): The charging time is required to be 1~5 minutes, the measured value must be stable, and the insulation resistance of the outer sheath is not less than 0.5MΩ/km;

- AC withstand voltage test: Cables with rated voltages below 18/30kV can use 3U0’s 0.1Hz voltage instead of the power frequency test to reduce equipment capacity requirements;

- Partial discharge test (GB/T 3048.12): Detect insulation defects, and the sensitivity must reach pC level.

International standards such as IEC 60502 put forward unified requirements for the withstand voltage level and structural design of 1~30kV cables, promoting the standardization of the global supply chain.

4. Synergy and differences between international and domestic standards

Globally, rubber and plastic cable standards present a “dual-track parallel” feature:

- International standards (IEC): represented by IEC 60227 (general requirements) and IEC 60502 (medium and high voltage cables), emphasizing electrical performance and safety thresholds;

- Domestic standards (GB/T): such as GB/T 12706-2002 (equivalent to IEC 60502) and GB 50150-2016 (handover test specifications), which refine the test conditions in combination with the characteristics of China’s power grid. For example, GB 50150 stipulates that phase-separated shielded cables can be tested in multi-phase parallel to improve efficiency.

It is worth noting that DC withstand voltage test has been gradually replaced by AC withstand voltage and resonance tests because the electric field distribution does not match the actual working conditions, especially in cables above 35kV.

5.Test equipment and technological innovation

Rubber and plastic cable testing relies on high-precision equipment:

- Series resonant device: By adjusting the frequency, the withstand voltage test of large-capacity cables can be achieved, solving the problem of insufficient capacity of traditional power frequency transformers;

- High resistance meter and partial discharge detector: used for accurate identification of insulation resistance (10⁵~10¹⁶Ω) and tiny defects respectively;

- Environmental simulation chamber: simulates extreme conditions such as high and low temperature, humidity and heat to verify the long-term stability of cables.

Taking the irradiation cross-linking production line as an example, it integrates the electron accelerator and extrusion process to achieve real-time control of the cross-linking degree of the insulation layer, and improves production efficiency by more than 30%.

6. Expansion and Challenges of Application Fields

Rubber-plastic cables have penetrated into many fields such as energy, transportation, and military industry, but different scenarios have different requirements for standards:

- Power transmission: UHV cables (1000kV and above) need to solve the problems of corona loss and insulation aging;

- Rail transportation: Fire-resistant cables need to pass the flame propagation test of GB/T 19666 to ensure the integrity of the circuit during fire;

- Offshore wind power: Salt spray corrosion-resistant sheath materials (such as chloroether rubber) have become the focus of research and development.

Imported cables (such as 1~35kV grades) also need to meet additional operating conditions, including system grounding methods, short-circuit current duration and other parameters.

Summary

The technological progress of rubber-plastic cables has always revolved around the two cores of “safety” and “efficiency”. From material innovation to testing standard upgrades, the industry responds to diversified application challenges through standardization and technological innovation. In the future, with the popularization of smart grids and new energy, degradable sheath materials and online monitoring technology may become the next breakthrough point. Only by keeping up with the standard dynamics can manufacturers and users ensure the reliability and economy of cable systems in complex environments.