Winter Cable Protection Guide: Six Core Measures to Protect the Power Lifeline

Abstract:

The severe winter poses a severe challenge to the cable system. Threats such as low-temperature embrittlement, ice and snow load, and condensation moisture constantly test the reliability of power and communication networks. This article systematically expounds on six core protection strategies – from active temperature control, strict moisture-proof, connection reinforcement, scientific selection, intelligent inspection to ice and snow defense, to provide comprehensive technical guarantees for the safe wintering of cables and ensure that the city’s lifeline is indestructible in extreme weather.

1.Implement active temperature control protection to resist low-temperature embrittlement

Severe cold is the number one killer of cable insulation. When the temperature drops sharply, materials such as PVC lose their toughness, and slight bending can cause cracking. XLPE insulation also faces the risk of shrinkage and delamination. Active intervention is crucial: add rock wool tubes or foamed rubber and plastic insulation layers to the exposed sections to significantly delay heat loss; deploy constant power heating cables or self-limiting temperature heating cables at key nodes to maintain a safe temperature above 5°C through intelligent thermostats. The US Department of Energy’s technical guide emphasizes that buried cables need to pay special attention to the mechanical stress caused by changes in the permafrost layer, and the insulation layer needs to extend below the freezing depth line.

2.Build a full-range moisture-proof system to block the intrusion channel of water molecules

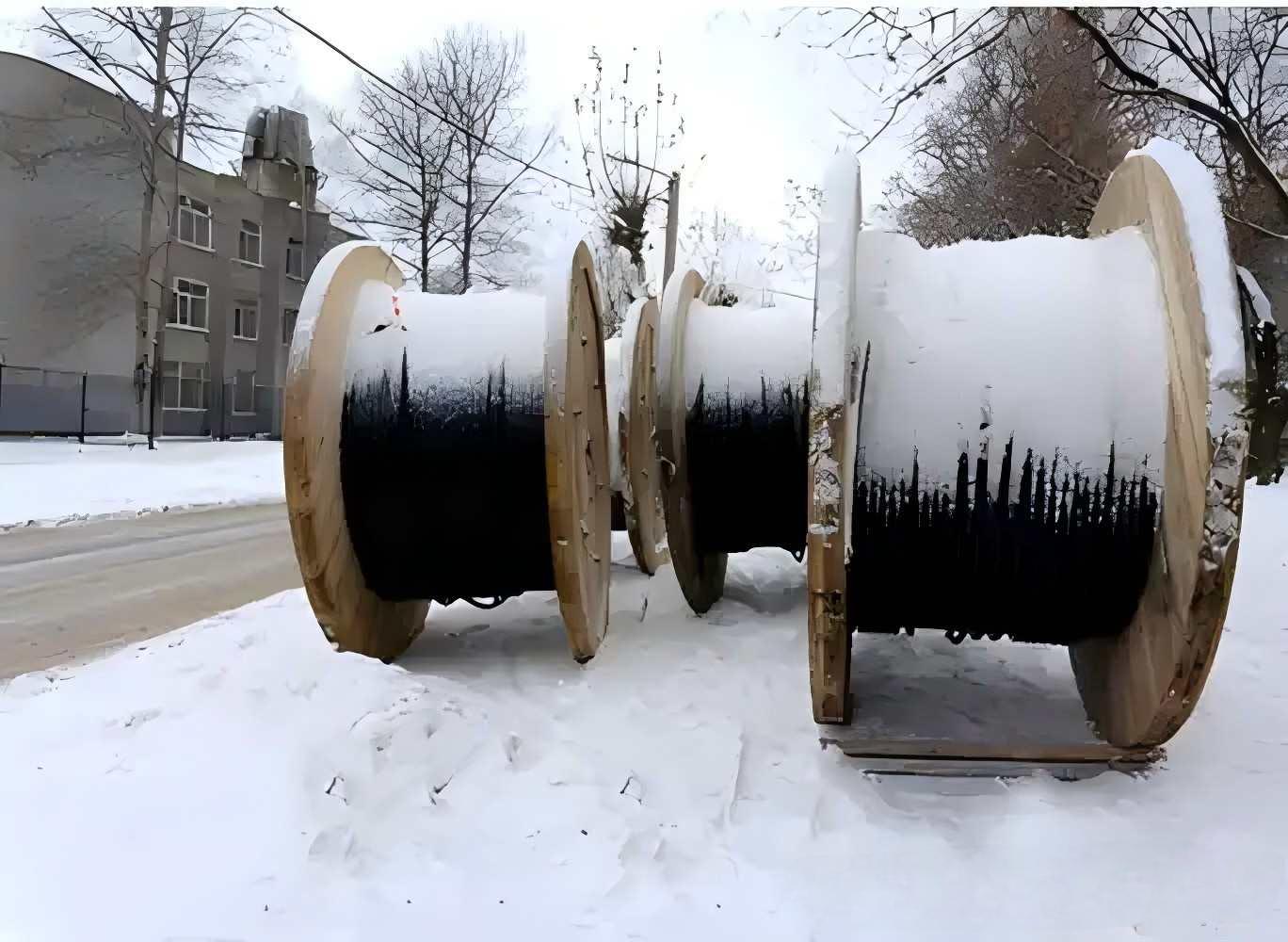

The temperature difference between day and night in winter generates fatal condensation. Water infiltration will cause water tree branches, accelerate insulation aging until breakdown. Protection needs to be two-pronged: adhere to the principle of “overhead + desiccant + temperature and humidity monitoring” during the storage stage; strictly check the integrity of the outer sheath during laying, use a triple waterproof box at the joint and inject special sealant (such as 3M™ Scotchcast™). The British Standards Association BS 7671 stipulates that underground cable trenches must be equipped with automatic drainage pumps, with a slope of not less than 0.5% to facilitate diversion.

3.Strengthen the connection point stabilization mechanism to prevent cold shrinkage failure

The shrinkage coefficient of metal at low temperatures is much higher than that of insulation materials. This physical difference makes the joint a weak link. Countermeasures include: using a torque wrench to tighten the crimped terminals to ensure that the contact pressure meets the standard; adding cold-shrink silicone rubber sleeves to outdoor terminals to compensate for shrinkage using its “elastic memory” characteristics; and promoting the use of silver-plated contacts to improve conductive stability. Case studies have shown that after a northern power grid adopted cold-shrink head technology in its transformation, the failure rate of winter joints dropped by 70%.

4.Scientific selection to match environmental needs and create innate cold-resistant genes

The cable’s own cold resistance level determines the bottom line of protection. The selection must follow: cold-resistant polyolefin sheathed or EPR insulated cables are preferred in high-cold areas (<-30℃); anti-kink TPE materials are used in frequent mobile scenes; direct burial installations must select anti-ant and moisture-proof armored cables. The International Electrotechnical Commission IEC 60502 standard points out that cables that have passed the “U-type low-temperature bending test” should be selected in a -40℃ environment.

5.Encrypt inspections combined with intelligent monitoring to build a dynamic defense network

Passive response is not enough to deal with winter risks. A “manual special patrol + online monitoring” system should be established: use infrared thermal imagers to scan temperature anomalies; use partial discharge detectors to capture insulation defect signals; deploy temperature and humidity sensors in underground cable trenches to link ventilation systems. IEEE papers confirm that distributed fiber temperature measurement technology (DTS) can achieve real-time monitoring per kilometer and accurately locate hot spots.

6.Establish an emergency response system for ice and snow disasters to resolve the impact of extreme weather

Ice and snow loads are a devastating threat unique to winter. Protection requires structural design: overhead lines use reinforced steel-core aluminum stranded wire (ACSR), and the span is shortened by 20% to reduce tension; vibrating deicers are installed on poles and towers; anti-icing coatings are pre-coated on key lines. The experience of the Hokkaido power grid in Japan shows that installing snow nets upstream of the cable radially can reduce the risk of snow accumulation by 60%.

Cables under the heavy pressure of ice and snow are like tight strings, and every break is a sudden stop in the city’s pulse.

Winter cable protection is a comprehensive battle against low temperature, moisture, and mechanical stress. Six measures – active insulation to isolate cold currents, three-dimensional moisture-proofing to lock in dryness, stable connection to resist shrinkage, scientific material selection to build a solid foundation, intelligent monitoring to predict risks, and ice and snow defense to relieve heavy pressure – constitute a systematic solution. Only by deeply coupling material science, structural design and intelligent operation and maintenance can we protect this “energy blood vessel” that maintains modern civilization in the severe winter, so that it can still burst out stable and surging vitality under the baptism of wind and snow. In the future, the combination of self-healing insulation materials and AI predictive maintenance will open up a new dimension for winter protection of cables.