The secret of the “invisible” breakpoints of cables is revealed! Six professional judgment methods can save 95% of faulty cables

Astratto:

The breakpoints of cables are like the “invisible wounds” of the circuit system. Accurate positioning is the key to efficient repair. This article systematically analyzes six core judgment technologies: digital multimeter method, induction electric pen method, broken line method, acupuncture method, audio detection method and telemeter method, covering full-scenario solutions from simple tools to professional instruments, and deeply explores their principles, key points of operation and applicable boundaries, providing an authoritative guide for electrical workers to locate breakpoints.

Cables are like the “nerves and blood vessels” of modern society. Their on-off status is directly related to equipment operation and energy security. However, when a fault occurs, the breakpoint is often hidden under the insulating sheath, and it is difficult to find it with the naked eye. How to efficiently, losslessly or minimally catch this “circuit ghost”? The following six methods build a systematic judgment system:

1. Digital multimeter method: Volt fluctuation locks centimeter-level error

- Principle: Utilize the significant voltage drop change of the AC electric field before and after the breakpoint. After the cable is connected to the live wire, a distributed capacitance is formed, and the multimeter detects the induced voltage on the surface of the insulation layer.

- Operation: The red test pen slides along the insulation layer, and the voltage value is usually stable at about 0.445V (according to the IEEE standard test environment). When the reading drops sharply to about 0.04V (1/10 of the original value), the breakpoint is pushed forward about 15cm here.

- Key limitation: When the shielding layer is intact, the electric field is shielded and the method fails. Authoritative reference: The National Institute of Standards and Technology (NIST)’s discussion on the distribution of AC electric fields.

2. Induction electric pen method: The signal disappearance point is the ten-centimeter bull’s eye

- Principle: Relying on the disappearance of the electromagnetic field caused by the current returning to zero after the breakpoint. The electric pen senses the alternating magnetic field around the cable.

- Operation: The electric pen moves slowly vertically to the cable, and its neon tube or LED indicator goes out within about 10cm after the breakpoint due to the interruption of the magnetic field.

- Scenario advantages: Especially suitable for quick initial screening of exposed cables. Make sure there is no interfering power supply around. Practice Guide: OSHA (US Occupational Safety and Health Administration) Electrician Safety Operation Specifications.

3. Broken Line Method: Mechanical stress triggers the on-off “pulse”

- Principle: Through physical bending, the conductor at the breakpoint is microscopically separated or contacted, causing a sudden change in resistance.

- Operation: Connect the ohmmeter of the multimeter at both ends of the cable, and bend it at a small angle from one end. The point where the needle jumps or the digital mutation point is the breakpoint.

- Applicability and warning: Only short cables (<20 meters) are recommended. Excessive bending may damage the intact wire core. Material science basis: Research on mechanical fatigue properties of conductors (ScienceDirect database).

4. Needle puncture identification method: Break the skin to see the true position, the ultimate means of caution

- Principle: Directly pierce the insulation layer and test the continuity of the conductor in sections.

- Operation: Insert a thin steel needle in sections and use a multimeter to measure the continuity between the needle and the end point. The breakpoint is locked when the continuity state changes.

- Major trade-offs: Although the positioning is accurate, the insulation layer is permanently damaged and requires subsequent professional repair, otherwise it is easy to cause leakage or short circuit (according to statistics from EC&M magazine, accidents caused by insulation damage account for as high as 32%). Industry warning: International Electrotechnical Commission (IEC) 60502 Cable Repair Standard.

5. Audio detection method: “sonar” tracking of underground faults

- Principle: Inject a specific frequency audio current into the faulty cable, the surface receiver captures the magnetic field signal, and the signal attenuates or distorts at the breakpoint.

- Operation: Connect the audio generator to the cable, and use the handheld probe to detect along the path. The point where the signal suddenly weakens corresponds to the breakpoint below.

- Core value: The only non-destructive positioning solution for direct buried or piped cables, with an accuracy of within 0.5 meters. Technical deepening: Electronic Power Research Institute (EPRI) Underground Cable Diagnosis Report.

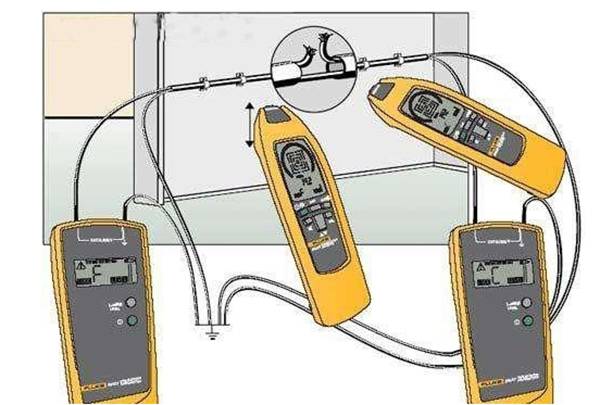

6. Cable Fault Telemeter: “General Practitioner” for Complex Networks

- Principle: Combine time domain reflectometry (TDR) and high-voltage pulse technology. TDR transmits pulses and receives reflected waves, and determines the distance to the breakpoint based on time delay and waveform; high-voltage pulses are used to burn through high-resistance fault points.

- Full-view function: It can accurately measure the full length of the cable, diagnose open circuit (breakpoint), short circuit, and ground fault, with an error rate of <1%. Industry benchmark: Megger Cable Fault Locator Technical White Paper.

There is no “master key” for breakpoint determination, the choice of method is a precise balance between cost, accuracy and scenario:

- Rapid screening of open wires: The induction electric pen method and the broken line method have the lowest cost;

- Precise centimeter positioning: The digital multimeter method and the needle puncture method (use with caution) have significant advantages;

- Underground concealed engineering: The audio detection method is irreplaceable;

- Full-parameter professional diagnosis: The cable fault telemeter is the ultimate solution for complex systems.

Every precise positioning is a “microsurgery” on the power veins. Mastering these six technical keys can not only significantly reduce downtime caused by faults, but also avoid the risk of secondary damage caused by blind troubleshooting through scientific operations – in the silent battlefield of current and insulation, method is efficiency and knowledge is safety.