Abstract

In the field of home decoration and electrical safety, the choice of wires is crucial. However, consumers often fall into a variety of misunderstandings when buying wires, which may lead to safety hazards or inconvenience in use. This article will deeply analyze six common misunderstandings, including only focusing on price and ignoring quality, ignoring the quality of materials, purchasing “three-no” products, not considering the installation environment, confusing specification loads, and despising flame retardant certification. Combined with authoritative data and professional advice, it provides a scientific pit avoidance guide to help you buy safe and applicable wires and ensure the safety of household electricity.

1. Only look at price and ignore quality: low-price traps hide safety hazards

In the purchase of wires, price is often the most intuitive decision-making factor for consumers. However, according to the 2023 spot check data of the State Administration for Market Regulation, the qualified rate of low-priced wires is only 67.3%, significantly lower than the 89.2% of average-priced products. Many low-priced products use recycled plastic to make insulation layers to reduce costs. The copper core contains less than 95% copper, and even contains impurities such as lead and zinc. This type of wire is prone to aging and cracking of the insulation layer and decreased conductivity in long-term use. The risk of short-circuit fire is 3.2 times higher than that of qualified products (data source: China Quality Certification Center). Pit avoidance guide: Choose products that have passed CCC certification and look for the “China Energy Efficiency Label”. The insulation layer of regular brand wires feels flexible, and the inner wall is smooth and free of impurities after peeling; the copper core is uniform purple-red and rebounds naturally after bending. You can refer to the product quotations of well-known brands such as Zhujiang Cable. The average price range can usually guarantee basic safety performance (external link: https://www.zhujiangcable.com).

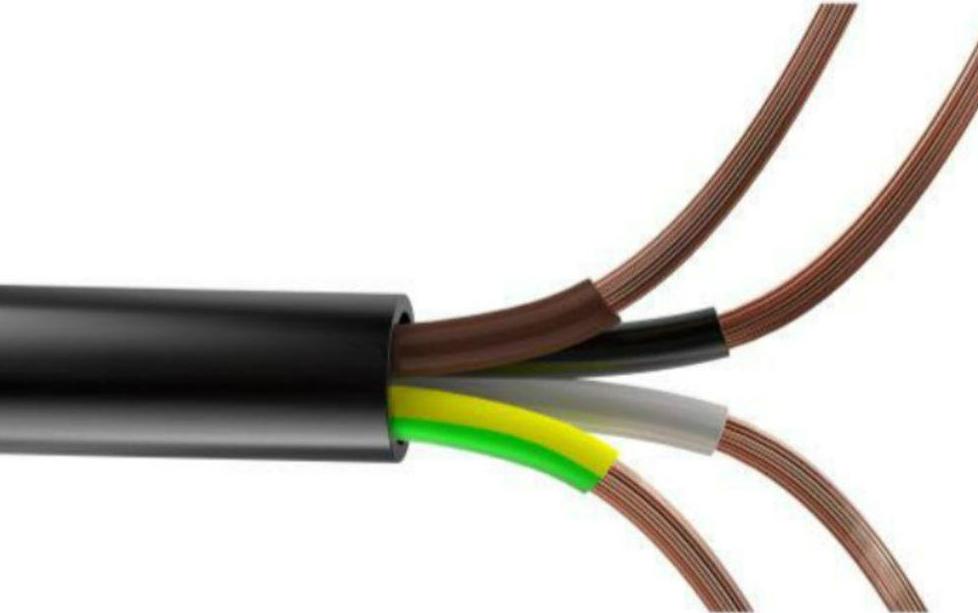

2. Ignoring material differences: The performance gap behind the copper-aluminum dispute

Wire conductors on the market are mainly divided into copper core and aluminum core, and the performance difference between the two is significant. The conductivity of aluminum core wires is only 61% of that of copper cores, and the joints are prone to oxidation and resistance, resulting in local heating. Statistics of fire accidents in a certain province in 2022 show that fires caused by overheating of aluminum core wire connectors accounted for 18.7%. The “brass” (copper content < 90%) common in inferior copper cores has a 15% lower conductivity than pure copper and higher energy loss. Identification skills: Pure copper cores should have “three bright” characteristics – bright skin (uniform luster), bright cross section (no pores), and bright bends (obvious metallic luster on the fracture surface). For humid environments (such as kitchens and bathrooms), tinned copper core wires should be selected, and their antioxidant capacity is 40% higher than that of ordinary copper cores (external link: https://www.cqc.com.cn).

3. Trust “three no” products: lack of certification equals safety blind spots

“Three no” products are wires without factory name and address, quality certificate, and implementation standard number, and their market share in urban and rural areas is about 15% (2024 building materials market research data). This type of product has not passed the national standard test such as GB/T 5023, JB/T 8734, etc. The thickness of the insulation layer may be 20% thinner than the standard value, and the temperature resistance level is less than 70℃ (qualified products need to be ≥90℃). After-sales data of a decoration platform shows that the failure rate of “three-no” wires is 6.8 times that of regular products. Purchase points: Look for complete “three-standard” information – the packaging should be printed with the production license number (XK06-001), the implementation standard number (such as GB/T 5023.3-2008), and the factory name and address. For regular brand products, you can query the anti-counterfeiting information by scanning the QR code, such as Zhujiang Cable, which has an independent anti-counterfeiting code on each roll of wire (external link: https://www.nqi.org.cn).

4. Confusing specifications with load requirements: a fatal mistake of a small horse pulling a big cart

The wire specifications (such as 1.5mm², 2.5mm²) directly determine the current carrying capacity. If the selection is improper, it is easy to cause overload. In common household scenarios, it is recommended that lighting circuits use 1.5mm² (current carrying 18A), ordinary sockets require 2.5mm² (current carrying 26A), and air conditioning/kitchen dedicated lines should use 4mm² (current carrying 38A). However, the survey shows that 32% of owners misuse 2.5mm² wires in kitchen circuits, resulting in a 55% increase in the peak trip rate. Calculation method: Based on the total power of the appliance (P=UI), such as a 1000W appliance current of about 4.5A. It is recommended to reserve a 20% safety margin, that is, the total load current does not exceed 80% of the current carrying capacity of the wire. Please refer to Section 8.5 of the “Residential Design Code” GB 50096-2011 for specific provisions on wire selection (external link: https://www.gbstandard.cn).

5. Ignoring environmental adaptability: invisible killers in special scenarios

Different use environments have special requirements for wire performance: humid environments require waterproof types (such as RVV sheathed wires), high temperature places (such as wall-mounted furnaces) require cross-linked polyethylene insulated wires that can withstand more than 105°C, and fume environments should choose smooth polyvinyl chloride insulation layers to reduce dirt accumulation. A community used ordinary BV wires in the bathroom, and 7 short circuit accidents occurred in 5 years, all because water vapor penetrated the insulation layer and caused leakage.

6. Disregarding flame retardant certification: the key line of defense for fire escape

In a fire accident, ordinary wires will release a lot of toxic smoke when burning, and the flame spreads quickly. Wires with flame retardant certification (such as ZA and ZB grades) use halogen-free flame retardant materials, and the smoke density is ≤75% when burning, and the release of toxic gases is reduced by 60%, which buys precious time for people to escape. However, only 42% of decoration projects in the market use flame-retardant wires, and the usage rate of small and medium-sized decoration companies is even lower, at 28% (data source: China Fire Protection Association). Certification identification: The packaging of flame-retardant wires should be printed with “ZC” (C-level flame retardant), “ZB” (B-level) and other logos, and must comply with GB/T 19666-2019 “General Rules for Flame-retardant and Fire-resistant Wires, Cables or Optical Cables”. It is recommended to choose ZA-level or above products for important places (such as living rooms and bedrooms), with an oxygen index of ≥32%, which is significantly better than the 26% of ordinary wires (external link: https://www.fire.org.cn).

Summary: The “three-dimensional rule” of scientific purchase

To avoid misunderstandings in wire purchase, it is necessary to establish a three-dimensional evaluation system of “quality – specifications – environment”: first, the basic quality is guaranteed by certification marks and brand reputation, secondly, the specifications are accurately matched according to load requirements, and finally, professional models are selected according to environmental characteristics. It is recommended to give priority to products that have passed international certification (such as CE, UL), which have stricter production process control and safety improvement of more than 30% (external link: https://www.ul.com). Remember, as the core component of concealed engineering, the service life of wires should be synchronized with the building (usually ≥50 years). Short-term cost savings may lead to high maintenance costs or even safety accidents in the future. Only by adhering to the principle of “safety first, adaptation first” can we build a solid safety line for household electricity. When purchasing, you may wish to refer to the annual quality report of the authoritative organization, and make a comprehensive decision based on the specific usage scenario, so that every meter of wire can become a safety guard to protect the family.