The safety code behind the core color: Identify inferior cables at a glance

In electrical fire accidents, nearly 30% are caused by inferior wires and cables. When consumers face the uneven cable products on the market, an overlooked truth comes to the surface: the core color is not only a visual identification, but also the first line of defense for judging the quality of the cable.

1. National standard color spectrum: the standard code of color

The color code of the insulated core of my country’s cable is by no means set arbitrarily. According to the GB/T5023-2008 standard:

- The grounding wire must use yellow-green combination color, and any color must cover 30%-70% of the core surface

- The neutral line is uniformly marked with light blue

- The standard color spectrum of three-core cable is yellow-green, light blue, and brown

- The four-core cable is yellow-green, light blue, black, and brown

These mandatory specifications constitute the “identity language” of the cable. When the 3×10mm² cable in a residential project has an unconventional “yellow, green and yellow” tricolor, even if the electrician temporarily marks the neutral ground wire with a heat shrink tube, it violates the standard’s technical requirements for permanent color identification.

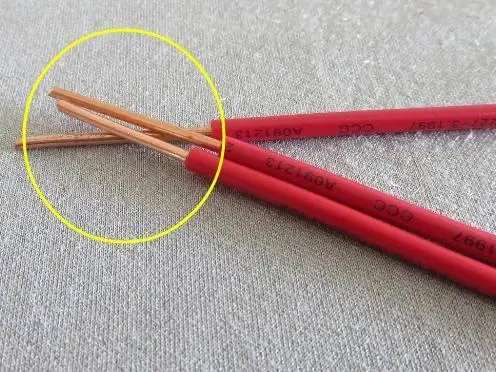

2. The true color of the copper core: a touchstone of purity and safety

Peeling off the insulation layer, the true color of the copper core will reveal the essence of the material:

- High-quality oxygen-free copper presents a purple-red metallic luster, with a conductivity of up to 101% IACS

- Poor-quality copper core reveals a danger signal:

- White color: indicates that zinc and tin impurities exceed the standard

- Yellow with white: Abnormal iron and lead impurity content

- Purple and black without light: The recycled copper has too high oxygen content

Rubbing the inferior copper core with white paper will leave obvious black residue – this is ironclad evidence of excessive metal oxides. The resistance of this type of conductor increases by more than 20%, causing a sharp drop in the current carrying capacity of the cable, becoming an invisible fuse for electrical fires.

3. Color distribution: a magnifying glass for process quality

The color distribution of the yellow-green two-color cable can be called a process test paper. The national standard stipulates that the two-color coverage must meet the following requirements:

- The main color (yellow or green) accounts for 30%-70%

- The color boundary is clear and impermeable

Poor-quality products often have imbalanced color ratios or blurred boundaries, which directly exposes:

- Unqualified insulation material formula

- Out-of-control extrusion process temperature

- Insufficient precision of production equipment

Data from a certain testing agency show that the failure rate of insulation withstand voltage test for cables with unqualified two-color ratios is as high as 65%.

4. Abnormal color: Alarm of material degradation

When the core shows unusual color changes, it often indicates serious quality problems:

- Yellowing insulation layer: Excessive addition of recycled materials, insufficient anti-aging agent

- Dark copper core: Copper clad aluminum is counterfeited, aluminum core copper plating deceives consumers

- Uneven color: Insufficient mixing of impurities, poor material stability

Especially for inferior copper clad aluminum wire, the cross section can be seen to have obvious “yellow and white stratification” phenomenon – the outer thin copper wraps the white aluminum core. The conductivity of this material is only 61% of pure copper, while the thermal expansion coefficient is 40% higher, and the risk of joint loosening is doubled.

5. Marking integrity: the mirror image of compliance

The marking system of regular cables is an extension of quality management:

- Must include elements: CCC certification number, voltage level, factory name, specification model

- Printing requirements: clear handwriting and wiping resistance, repeated mark spacing ≤50mm

The logos of three-no products are often blurred and incomplete, and even deliberately marked with ambiguous “Made in China”. Products without the CCC certification mark have a failure rate of more than 80% in market supervision spot checks.

6. Actual combat case: The cost of the color crisis

After a residential project used non-standard color spectrum cables, the electrician illegally changed the yellow-green line to the neutral line. Three months after delivery:

- 16 owners reported that their appliances burned

- Testing found that the phase connection error rate was 41%

- The rework cost reached 15% of the project cost

The root cause of the accident was that the non-standard color caused confusion in the wiring, causing the 380V phase voltage to enter the 220V circuit by mistake.

Auxiliary identification method

In addition to color, comprehensive verification can improve the accuracy of judgment:

| Test method | Operation method | Qualified standard | Poor quality performance |

|---|---|---|---|

| Bending test | Repeated bending of wire ends | No cracks in the insulation layer, good elasticity | Deep creases, brittle cracks |

| Weighing verification | Weighing 100 meters | 2.5mm²≥3kg | Weight less than 3kg |

| Length verification | Measure the length of the entire roll | 100±0.5 meters | Only 65-95 meters |

| White paper test | Copper core rubbing white paper | No black residue | Obvious black matter |

| Burning test | Flame burning copper wire | Only slight discoloration | Softening and deformation |

When a cable manufacturer increased the green proportion of the yellow-green two-color grounding wire to 75%, the product passed the routine test but was judged as unqualified in the UL certification – The color gamut range of 30%-70% is not only a technical specification, but also a quantitative expression of the safety boundary. The color spectrum system of modern cables is like a precise biological gene map, and each color is an explicit expression of material characteristics, process level and safety commitment. Mastering this set of visual codes, consumers have the ability to penetrate the marketing fog, allowing every inch of the cable core to tell the safety truth under professional scrutiny.