Insulation resistance determines cable life! Analysis of six core factors and new material breakthroughs

The insulation resistance of wires and cables is like the immune system of the power system. It is invisible and intangible, but it determines the safety and life of the entire power network.

The insulation resistance of wires and cables is the core indicator for evaluating their insulation performance, which is directly related to the safety and efficiency of power transmission. In the power system, insulation resistance drop is one of the main causes of cable failure, which may cause serious consequences such as short circuit and fire.

According to the national standard GB/T 3048.5-2007, the insulation resistance value of 6~10KV cables should not be less than 400MΩ, while 20~35KV high-voltage cables must reach more than 600MΩ. These values seem abstract, but they indicate the health of the system like the blood pressure value of the human body.

Material factors: the foundation of insulation performance

The inherent characteristics of insulating materials are the prerequisites for determining the insulation resistance of cables. The molecular structure and chemical properties of different materials directly affect their resistivity performance:

- Cross-linked polyethylene (XLPE): It has a highly cross-linked molecular structure and its resistivity is significantly better than that of traditional PVC materials, making it the mainstream choice for medium and high voltage cables.

- Silicone rubber: The special silicone molecular chain gives it wide temperature range stability, and can maintain resistance stability in an environment of -60℃~+180℃, especially suitable for extreme environments such as metallurgy and chemical industry.

- Material purity: When the impurity content exceeds 0.01%, metal particles or moisture will form a conductive channel, causing the insulation resistance to drop by up to 30%.

Material aging is another invisible killer. Thermal aging will cause the polymer chain to break, and electrical aging will cause partial discharge to form a carbonization channel. Test data shows that if unqualified products are used, the life of Class B insulation materials that work at 130℃ for a long time will be shortened by more than 40%.

Temperature and humidity effect: resistor killer in the environment

The effect of temperature and humidity on insulation resistance shows an exponential change law:

- For every 10℃ increase in temperature, the insulation resistance may drop by more than 50%. For example, the insulation resistance value of the control cable at 70℃ is only 10% of that at 20℃. This is because the molecular thermal motion intensifies and the ion mobility increases, resulting in a surge in leakage current.

- Humidity exceeds 70%: Water ionization produces conductive ions, especially forming a conductive film on the surface of the material, which increases the surface leakage current. What’s more dangerous is that water infiltration will form water dendrites, which will eventually develop into electrical dendrites and cause breakdown.

The synergistic effect of moisture and heat is particularly deadly: a change from 25℃ to 100℃ may cause a 100,000-fold change in resistance, and a change in humidity from 25% to 95% can also bring a 100-fold impact. This explains why the cable failure rate in humid areas in the south is significantly higher than that in dry areas.

Electric field and structure: invisible stress damage

The matching degree between electric field strength and insulation structure is the core challenge of high-voltage cable design:

When the operating voltage exceeds the design threshold, electric field distortion will cause local discharge (corona phenomenon). This continuous discharge is like repeatedly piercing the insulation layer with a needle tip, gradually eroding to form a carbonized channel. Space charge accumulation will also occur under DC voltage, further distorting the electric field distribution.

The design of insulation layer thickness must follow the “golden ratio”:

- Increasing the thickness by 50% can increase the insulation resistance by about 60%

- But too thick will cause heat dissipation difficulties and cost surges

Structural defects are latent “time bombs”. The inspection rules of Shaoxing Market Supervision Bureau specifically emphasize: Bubbles, cracks or impurities in the insulation layer will cause a sudden drop in local resistance, causing dendritic discharge in long-term operation. Damage to the armor layer will cause the cable to lose mechanical protection and accelerate erosion by environmental factors.

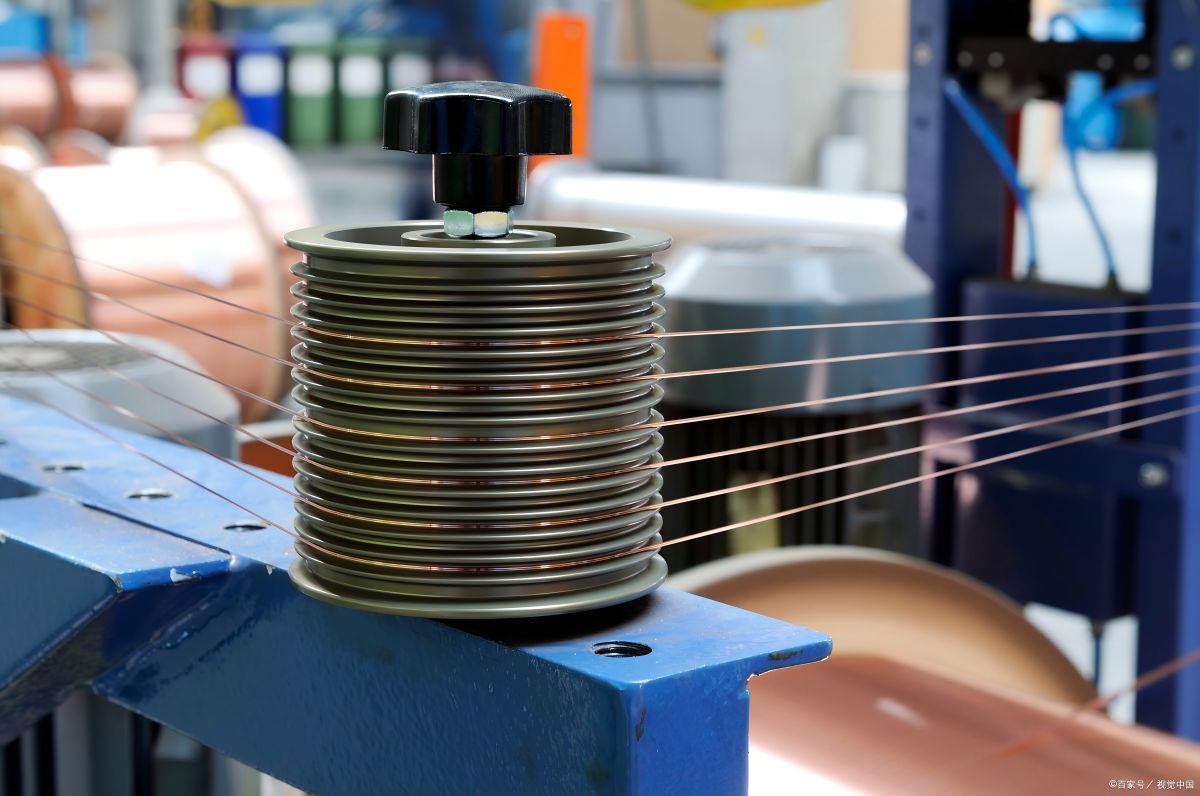

Manufacturing process: Quality game from laboratory to workshop

Even if high-quality materials are selected, slight deviations in the production process may lead to a cliff-like drop in insulation performance:

- Extrusion process: Temperature fluctuations exceeding ±5℃ may produce pores; improper cooling rate may cause internal stress cracks.

- Cross-linking process: For XLPE cables, cross-linking degree less than 90% will directly reduce heat resistance and insulation performance.

- Cleaning control: Fault analysis of a cable factory shows that if 1,000 dust particles are added per cubic meter in the production environment, the qualified rate of finished product insulation resistance will drop by 12%.

Zhejiang Will Eagle Company’s latest patent (CN120197070A) solves this problem through the AI dynamic temperature control system: Based on the comprehensive value of the cable and historical data, the preparation temperature is adjusted in real time to control the process fluctuation within ±1℃, significantly improving the insulation uniformity.

Environmentally friendly new materials: Green revolution in insulation technology

Traditional PVC cables contain heavy metals such as lead and cadmium, which pollute soil and water sources after being discarded. Its environmentally friendly alternatives have become the focus of the industry:

- Polypropylene insulated cable: No cross-linking process is required, and the production process is zero pollution. The operating temperature can reach 105℃, and the current carrying capacity is more than 10% higher than that of traditional XLPE cables. Tens of thousands of kilometers have been deployed in Europe, and my country’s Southern Power Grid’s 110 kV grafted polypropylene cable has passed type testing.

- Recyclable thermoplastic elastomer: The products developed by Jinbei Electric can be 100% recycled and reused after being discarded, breaking the pollution dilemma of the “cable graveyard”.

- Three-layer wrapped insulated wire: Suzhou Taiweida’s patented technology (CN119252575A) uses three layers of PPS/PET tape for wrapping, and the withstand voltage between any layers reaches 3KV, providing double protection for precision electronic equipment.

These innovations not only meet the requirements of EU RoHS directive and other regulations, but also raise the cable insulation resistance temperature index to H level (180℃), meeting the 27% annual growth demand in the new energy field.

Full life cycle protection strategy

From installation to scrapping, cable insulation resistance requires systematic protection:

- Laying stage: Excessive bending will squeeze the insulation layer, and dragging and friction will cause micro cracks. The specification requires that the bending radius should not be less than 6 times the outer diameter (shielded cable needs 10 times).

- Operation monitoring: The intelligent online monitoring system can provide real-time warning of the insulation resistance decline trend. After application in a chemical plant, the failure rate dropped by 65%. The secret is to set 1MΩ as the shutdown threshold.

- Diagnostic technology: Megaohmmeter test must strictly follow GB/T 3048.5 standard:

- 1KV or less cables use 1KV megohmmeter

- Test time is controlled within 1 minute

Regular testing is like doing an “electrocardiogram” for the cable:

- Quarterly testing finds that the resistance drops by >20%: warning of accelerated aging

- Annual drop >50%: must be replaced

Insulation technology is undergoing a revolutionary breakthrough. Yanshan Petrochemical’s 110 kV cable insulation material has achieved an annual production capacity of 25,000 tons, which is used in high-end fields such as deep-sea cables. Suzhou Taiweida’s three-layer wrapping patent increases the insulation layer’s withstand voltage by 300%.

The future belongs to self-healing insulation materials – when micro-damage occurs, the active ingredients in the material can automatically fill the cracks. As the power engineer said: The invisible insulation resistance determines the visible power safety. Only with full-chain innovation from material genes to intelligent monitoring can a truly safe power network be built.