The choice of a cable determines whether the power system becomes an escape route or a deadly trap in a fire

In modern buildings and industrial facilities, fire safety design is like a silent guardian, and cable selection is its core link. Flame-retardant cables and fire-resistant cables are often mentioned together, but they play completely different roles in fires.

When the flames start, the flame-retardant cable curbs the spread of the fire through its self-extinguishing characteristics, buying time for the evacuation of personnel; while the fire-resistant cable can still transmit power stably in the flames to ensure the continuous operation of fire-fighting equipment – the two are like “defenders” and “defenders” in the fire-fighting system.

1. The essential difference in fire prevention mechanisms

- The core mission of flame-retardant cables: “firewalls” that prevent flames from spreading along cables The secret of flame-retardant cables lies in their special material formula. When encountering flames, the flame retardant in its sheath self-extinguishes through the halogen flame retardant effect or the precipitation of water vapor to cool down, and can automatically extinguish within 12 seconds after removing the fire source. This feature effectively curbs the “fire path” formed by flames passing through cable trays or shafts, especially in high-density laying scenarios, which can prevent a single ignition point from evolving into a disaster of burning the entire line.

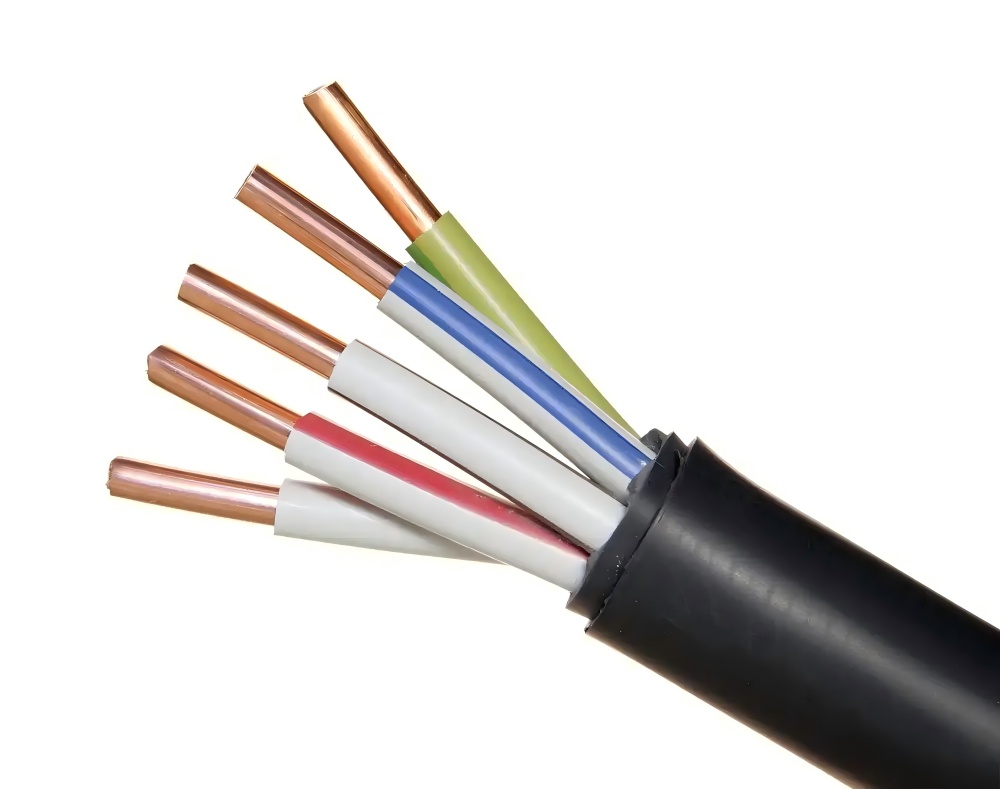

- Unique design of fire-resistant cable: the “lifeline” maintainer in high temperatures The secret of fire-resistant cable lies in the mica tape fire-resistant layer between the conductor and the insulation layer. Mica, as a natural mineral, has a melting point of up to 1200℃ and can still maintain its insulation function in a flame of 800℃. Even if the external polymer is burned, this “golden bell” can ensure that the line is normally powered on within 180 minutes. For example, mineral insulated fire-resistant cable (MI cable) can maintain lossless operation for 30 minutes at a high temperature of 1000℃, providing key power support for firefighting and rescue.

2. Multi-dimensional competition of safety performance

- Toxic smoke control: invisible life killer The hydrogen chloride (HCl) gas released when traditional halogen-containing flame-retardant cables burn will form hydrochloric acid when it meets water vapor, causing fatal damage to the respiratory tract. The halogen-free flame-retardant cable (WDZ-B1) that meets the B1 level reduces the generation of toxic gases by more than 90% and the smoke concentration by more than 80%.

In the simulation experiment of Tianjin Fire Research Institute, the visibility of B1-level cable was maintained at more than 30 meters when burning, which is much higher than the escape threshold of 10 meters, which is crucial for the evacuation of personnel in closed spaces such as subways and tunnels.

- Fire-resistant time and power guarantee: a life-and-death contest of every second The core indicator of fire-resistant cable is the time to maintain power supply. The national standard GB/T 19666-2019 stipulates that Class A fire-resistant cable must continue to supply power for more than 90 minutes in 950-1000℃ flames, while high-quality products such as NH-YJV type can even reach 180 minutes.

In the 2017 Beijing Daxing fire, the emergency lighting system failed within 15 minutes due to the lack of fire-resistant cables, exacerbating the evacuation chaos; in contrast, the Shanghai Tower uses a three-level fire-resistant line, and its fire protection system continued to supply power for more than two hours in the simulated fire test.

3. Strategic selection of application scenarios

- The main battlefield of flame-retardant cables: a “safety net” to curb the spread In ordinary commercial complexes and residential projects, flame-retardant cables constitute the first line of defense. Especially for vertical cable wells in super-high-rise buildings (height>100 meters), Class B1 flame-retardant cables can effectively curb the “chimney effect” and prevent the fire from spreading vertically along the well.

The case of Qingdao Haitian Center shows that after using WDZ-B1 cables, the flame spread distance in the bundled combustion test is only 0.8 meters, which is far below the national standard limit of 1.5 meters.

- Fire-resistant cable life channel: the “guardian” of key systems In hospital operating rooms, nuclear power plant control systems, subway tunnels and other places, fire-resistant cables are irreplaceable “lifelines”:

- Fire pump power lines: ensure continuous water supply

- Smoke exhaust fan lines: maintain visibility of escape channels

- Alarm system circuits: avoid interruption of evacuation commands

- The entire Shanghai Metro Line 18 adopts NH-YJV fire-resistant cable + halogen-free flame-retardant sheath double protection, which can not only maintain the operation of the signal system in the event of a fire, but also prevent the harm of toxic smoke.

4. Complementary applications create safety redundancy

- Graded protection strategy: building a defense-in-depth system The smart fire protection design adopts the “zoning + grading” cable layout:

- General area: ZRB-grade flame-retardant cable (such as ZR-YJV)

- Crowded area: WDZ-B1 halogen-free low-smoke flame-retardant cable

- Lifeline system: NH-YJV fire-resistant cable + mica tape reinforcement

- Core equipment: mineral insulated fireproof cable (MI cable)

In the cable solution of Shenzhen Ping An Financial Center, ordinary load lines use B1-grade flame retardant, while fire pumps and ICU ward power supplies use mineral insulated cables, forming a multi-level protection.

- Synergistic efficiency enhancement technology: physical isolation and intelligent monitoring Even if high-performance cables are selected, they must be coordinated with:

- Fireproof partition: Fireproof partition walls are set up every 60 meters in the cable tunnel, and ceramic silicone rubber sealing modules are used

- Temperature monitoring: Temperature-sensitive optical fibers are laid in the bridge frame to detect hot spots in real time

- The cable well of China Zun Building adopts fireproof plugging with a fire resistance limit of ≥2 hours every three floors, and is connected to the BA system for automatic alarm.

5. Market chaos and standard evolution

- Shocking cost of counterfeiting In the fire in Huojia Industrial Park in Shanxi in 2020, the case of counterfeit and shoddy cables causing a loss of 3.5 billion yuan was written into the “2025 China Cable Industry Fire Protection White Paper”. The test showed that the flame retardant performance of the cable involved was only Class C (the national standard requires Class B1), and the mica tape content in the fire-resistant layer was less than 40% of the standard value.

- Standard upgrade drives industry reshuffle GB/T 19666-2019 new regulations increase the self-extinguishing time of bundled combustion of Class B1 flame-retardant cables from 30 minutes to 60 minutes, and the smoke transmittance requirement is increased to more than 80%. The EU CPR regulations also require cables to be marked with smoke toxicity levels (such as s1a and d1), forcing Chinese companies to upgrade their technology. Zhujiang Cable and other leading companies have launched flame-retardant and fire-resistant integrated products**, which use radiation cross-linking technology to make the sheath temperature resistant to 125°C and extend its life by 10-15 years.

6. Golden rules for scientific selection

- Scenario-based decision matrix

- Commercial residential: WDZ-B1 cable is used in public areas (such as elevator shafts)

- Data center: B1 flame retardant + ceramic fire retardant coating is used for the main line

- Oil platform: Oil-resistant flame retardant cable + IA fire resistant double protection

- Hospital operating room: Mineral insulated cable (guarantee 2 hours of power supply)

- Four-step method for counterfeit identification

- Check the logo: B1 flame retardant should have “WDZ-B1” printed, fire-resistant cable marked “NH”

- Test report: Log in to National Certification and Accreditation Information Public Service Platform to check the validity of 3C certificate

- Measure the structure: Peel off the cross section, the coverage of mica tape of fire-resistant cable should be ≥80%

- Make slices: Send for inspection and combustion test, genuine B1 grade flame extension length ≤1.5 meters

There is no “master key” in the field of cable safety. Flame-retardant cables are like “fire doors” of buildings, cutting off the path of fire spread through self-extinguishing mechanisms; fire-resistant cables are like “emergency command centers”, sticking to power supply posts in flames.

When Tianjin 117 Building deploys B1 grade halogen-free flame-retardant cables and mineral insulated fire-resistant cables in the cable well at the same time; when a fire partition is set up every 50 meters in the tunnel of the Hong Kong-Zhuhai-Macao Bridge and triple protection cables are used – these super projects interpret the true meaning of modern fire protection: Safety is not a performance competition of a single material, but the art of system defense.

Cable fire performance classification and test standards (Source: GB/T 19666-2019):

| Performance category | Test items | B1 grade standard | Fire resistance grade A standard |

|---|---|---|---|

| Flame retardant performance | Flame spread of bundled combustion | ≤1.5 meters | – |

| Self-extinguishing time | Self-extinguishing time after removing the fire source | ≤60 minutes | – |

| Fire resistance | Power supply time at flame temperature | – | ≥90 minutes (950-1000℃) |

| Smoke density | Light transmittance | ≥80% | ≥60% |

| Toxic gas | HCl release | ≤5mg/g | ≤15mg/g |

Note: The performance of high-quality products usually far exceeds the basic requirements of national standards.

In the game between fire and life, scientific selection is not only a technical decision, but also a respect for life. When the last emergency light is still on due to the protection of high-quality cables, it is the most shining testimony of engineering ethics.