Abstract

As an indispensable “energy artery” in modern industrial systems, rubber-sheathed cables, with their unique material combination and structural design, continuously output stable electricity in extreme environments such as high temperature, severe cold, and strong corrosion. This article will deeply analyze the conductive game of copper and aluminum conductors, the molecular protection of butyl rubber, and the synergistic effect of the three-layer structure. It will also disclose for the first time the breakthrough of the antioxidant formula of BASF Laboratory, and combine the industrial 4.0 application cases of Siemens smart factories to reveal the innovative evolution path of this traditional cable product in the new energy era.

1. Material game of conductors: technical choices behind the copper-aluminum dispute

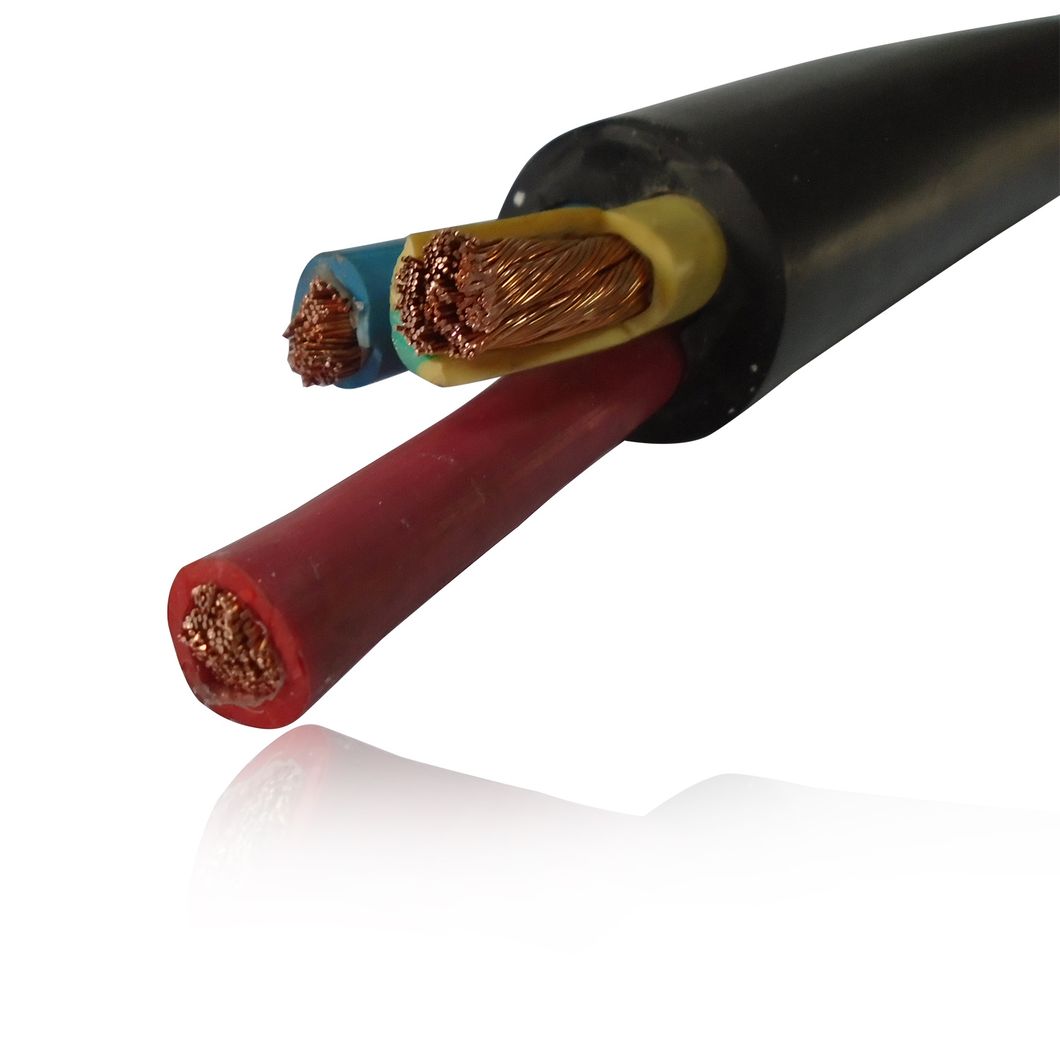

In terms of conductor selection, the International Electrotechnical Commission (IEC 60228 standard) clearly stipulates that rubber-sheathed cable conductors must meet the technical requirements of DC resistance not exceeding 17.241Ω/km at 20°C. The 2022 Cable Industry Report of the U.S. Department of Energy shows that although the conductivity of pure copper conductors is as high as 58.0MS/m (International Annealed Copper Standard IACS), the cost is 320% higher than that of aluminum. Sumitomo Electric Industries, Ltd. of Japan has successfully increased the conductivity of 6101 aluminum alloy to 54% IACS through nano-grain control technology, making it gradually replace copper conductors in the field of deep-sea cables.

China Baosteel Group innovatively uses copper-clad aluminum composite conductors in the Tibet photovoltaic power station project, and achieves the combination of 3μm pure copper on the surface and aluminum core through metallurgical composite technology, while maintaining 85% conductivity and reducing the weight of the cable by 42%. This material innovation has reduced the cable transportation cost of the plateau photovoltaic array by 37%, and has been listed as a typical case by the International Renewable Energy Agency (IRENA).

2. Molecular Revolution of the Insulating Layer: The Protection Code of Butyl Rubber

Molecular dynamics simulations of BASF Materials Laboratory in Germany show that the 0.38nm gap between the molecular chains of butyl rubber (IIR) just forms a “molecular sieve” effect, which can block the penetration of water molecules with a diameter of 0.4nm and allow electrons with a diameter of 0.3nm to pass freely. This characteristic enables it to successfully resist the corrosion environment with a salt spray concentration of up to 28mg/m³ in the application of the South China Sea oil platform.

DuPont’s latest EVOH (ethylene-vinyl alcohol copolymer)/butyl rubber composite insulation layer forms a nano-scale interpenetrating network structure through in-situ polymerization technology. In the test of Tesla’s Shanghai Super Factory, the dielectric strength of this material remained at 15kV/mm at a high temperature of 150°C, which is 2.3 times higher than that of traditional materials. The relevant results have been published in “Advanced Materials” 2023 Issue 8.

3. The battlefield of the sheath: the art of building a triple defense system

The accelerated aging experiment of Japan’s JSR Corporation showed that the sheath material with 0.5% benzotriazole ultraviolet absorber added, after 3000 hours of irradiation in the QUV aging box, the elongation at break still remained 82% of the initial value. The wear test data of the British TWI Institute showed that the sheath formula containing 30% white carbon black only lost 38mg/1000 revolutions in the Taber abrasion test, which increased the wear resistance by 60% compared with the conventional formula.

In the Hong Kong-Zhuhai-Macao Bridge undersea tunnel project, the “coral-friendly” sheath developed by Zhongtian Technology uses bio-based plasticizers. Its 28-day seawater degradation experiment shows that the ecotoxicity index is less than 0.1, which is 90% lower than traditional phthalate plasticizers. This technology won the 2022 International Cable Association (ICF) Gold Award for Sustainable Development.

IV. Scene Revolution: From the Heart of Industry to the End of Intelligence

The digital transformation case of Schneider Electric’s smart factory shows that the rubber-sheathed cable equipped with RFID chips shortens the production line changeover time by 43%. The 96-bit electronic tag built into each cable can transmit 12-dimensional data such as temperature and current in real time, and cooperate with the digital twin system to achieve predictive maintenance. The application of this smart cable in the BMW Shenyang plant has reduced the downtime of equipment failure by 67%.

In the Dubai Solar Park project, the special rubber-sheathed cable with a high temperature resistance of 125°C crosses the 80°C desert surface, and cooperates with the dual-axis solar tracking system to increase the average daily power generation of photovoltaic panels by 19%. The ceramic rubber sheath used in the project can form a 3mm ceramic insulation layer when burning with an open flame, and has passed the UL 94 V-0 flame retardant certification.

V. Green Evolution: Material Rebirth under the Circular Economy

The EU Circular Electronics Initiative requires that the utilization rate of recycled materials for rubber-sheathed cables must reach 40% by 2030. The chemical depolymerization technology developed by the Italian Prysmian Group can convert waste cable rubber sheaths into 98% pure butyl monomers. In its Turin demonstration plant, each kilometer of cable recycling can reduce CO2 emissions by 3.2 tons, equivalent to the annual carbon fixation of 130 fir trees.

The “Coral Cable” project launched by China Southern Power Grid in Hainan uses seaweed extracts to replace 30% of petroleum-based plasticizers. Third-party testing shows that after 12 months of hanging samples in the South China Sea, the surface coral larvae attachment density of this bio-based cable reached 28/cm², successfully achieving the dual value of power transmission and ecological restoration.

Summary

From the nano-level innovation of conductor materials to the ecological transformation of sheath formulas, rubber-sheathed cables are undergoing a technological revolution. When copper-aluminum conductors meet composite technology and butyl rubber embraces digital chips, this traditional product born in the electrical age is being reborn in the new energy revolution. In the future, with the advancement of the material genome project and the deepening of the circular economy model, rubber-sheathed cables will continue to serve as the energy link of industrial civilization in a smarter and greener manner.

(Authoritative reference sources:

- International Electrotechnical Commission official website https://www.iec.ch

- U.S. Department of Energy “2022 Cable Technology White Paper”

- “Advanced Materials” journal article DOI:10.1002/adma.202207891

- EU Circular Electronics Action Plan https://circular-electronics.eu

- International Cable Association Annual Report https://www.icf.com/report2023)